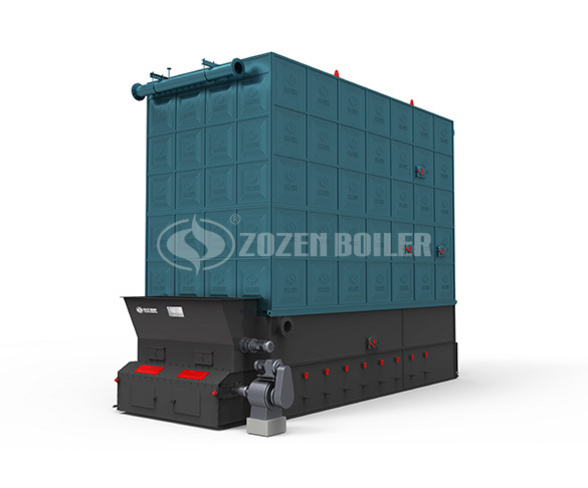

YLW Series Coal-fired/Biomass-fired Thermal Oil Heater

YLW thermal oil heater is square coil horizontal chain grate shop-assembled heater, chain grate and heater proper are transferred separately. It adapts chain grate to realize mechanical feeding coal, mechanical venting by blower and induced draft fan, and mechanical discharging by slag machine.

YLW series thermal oil heater featuers

-

Digitized manufacture

1.The laying-off of steel tube adopts CNC 3D laser cutting machine.2.The manufacture of square coil tube adopts CNC three-dimensional tube bending machine, no forced shaping.3.The manufacture of serpentuator adopts serpentuator automatic production line, once-forming. -

Full argon arc welding

1.Square coil tube and coil tube all adopt argon arc welding technique,which guarantees tubes are 100% qualified. -

Long life span

1.The optimized radiation heating surface and convective heating surface, the medium flow is more reasonable, without overheat of the carrier and reduce the life;2.Convection section: optimize convection heating surface and adopt effective fix and structural support to make its working life longer.3.Set up effective flue gas partition for convection heating surface and cast partition to make it works longer. -

Easy operation

1.We have combustion arch patent, which is available for different types of coals, even the anthracite is very easy to burn.2.Flame-proof feeding bucket can avoid the feeding bucket is burnt and coking.3.There is ash cleaning unit, which is easy for maintaining, operating and cleaning. -

Less fuel consumption

1.Use superior refractory brick to build inside and superior perlite in the middle. Keep the furnace temperature under 50℃ to make the minimization of loss.2.Furnace adopts double close line coil, which makes heating surface sufficient.

What We Do

PROFESSIONAL ANSWER

From boiler solution, optimization to installation, 24 hours online, provide technical support and avoid risks for you

ENGINEER SUPPORT

Based on user needs, we supply tailored service, boiler drawing&PID system, boiler room design, foundation drawings etc

AFTER-SALE SERVICE

Full-life After sale service. With our professional technical experts and service team, skilled technology provides customers with professional services

CONSTRUCTION

Our engineer on-site guidance installation and commissioning, ensure boiler running perfect, free training for boiler operator

According to the customer production requirements, provide professional boiler solutions, cost analysis, project investment budget, boiler drawing&installation and commissioning service