Case info

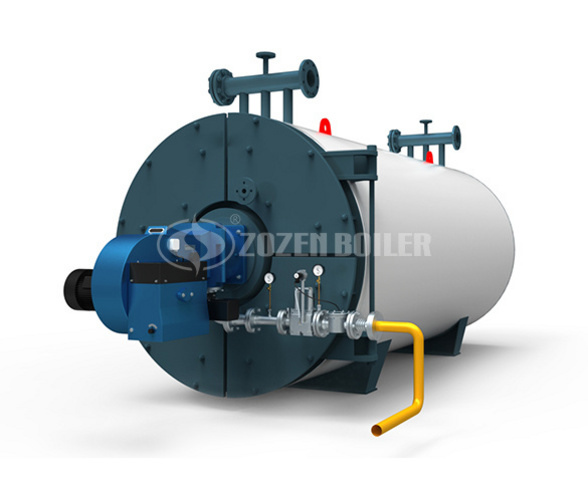

ZOZEN customizes SZS series biogas fired steam boiler systems for food factories with high efficiency and environmental protection. The superheated steam boiler uses biogas, a renewable energy source from the food factory, as fuel, which saves a lot of fuel costs for the enterprise. In the structure, the main body of SZS series biogas steam boiler adopts D type layout and membrane wall structure, which can greatly increase the radiation heating surface, fully ensure the sealing of the boiler, and increase the thermal efficiency of the boiler to more than 98%. In addition, the boiler is equipped with a reasonable size drum and a steam separator, which can effectively reduce the entrainment of water in the steam and improve the quality of steam.

15 tons SZS biogas boiler refers to the horizontal gas steam boiler, it is divided in accordance with the boiler body, use and fuel type. The rated evaporation capacity of a 15 ton gas steam boiler is 15 tons per hour, that is to say, it can produce 15 tons of steam per hour. ZOZEN’s biogas steam boiler thermal efficiency can reach more than 98%, which can effectively save the input cost for the food factory.

ZOZEN Boiler is indeed one of China’s leading qualified industrial Boiler manufacturers. Because of our special production technology, we put forward very high requirements for the temperature and quality of the steam produced by the steam boiler. However, ZOZEN not only recommended the appropriate SZS series superheated steam boiler according to our requirements for steam production, but also designed a reasonable biogas combustion system according to our requirements for fuel. We are very pleased with our cooperation with ZOZEN Boilers.