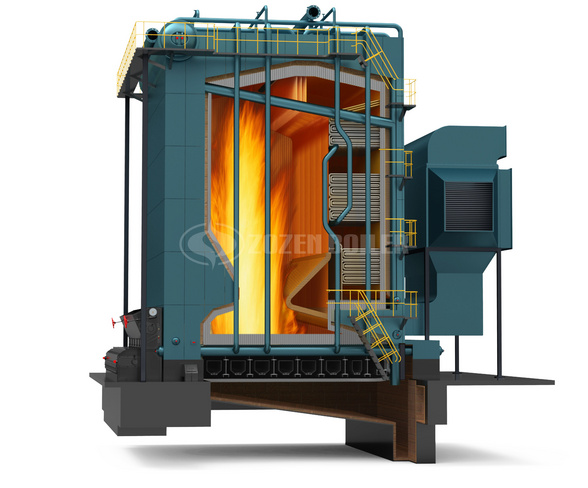

DHL Series Biomass-fired Steam Boiler

DHL corner tube boiler is field assembled boiler. The boiler drum is an external type drum, the furnace is a fully enclosed membrane wall structure, the convective heat absorbing surface adopts the flag tube structure. The corner tube boiler has the advantages of compact structure, low steel consumption and rapid temperature increase.

DHL biomass boiler features

-

Safe water circulation

1.The boiler adopts a unique water circulation structure, the drum is free from heat and the heated water flows in one direction. In the event of a power outage, the water system does not vaporize and the water circulation is safe and reliable. -

Anti-seismic Structure

1.Corner tube boiler adopts non-framework structure, boiler proper weight is supported by membrane wall and down comer, and all membrane walls are all welded into one whole, with good anti-seismicity. -

Complete sealed structure

1.All around the boiler proper is made of welded membrane walls, and the steel structure is completely sealed to prevent the occurrence of air leakage. The upper part of the boiler can be divided according to the size of the railway transportation limit. The excess air coefficient after the heating surface of the boiler tail is only less than 1.2, which not only reduces the heat loss of the exhaust fumes, reduces the power consumption of the induced draft fan, but also greatly reduces the environmental pollution of the boiler house.

What We Do

PROFESSIONAL ANSWER

From boiler solution, optimization to installation, 24 hours online, provide technical support and avoid risks for you

ENGINEER SUPPORT

Based on user needs, we supply tailored service, boiler drawing&PID system, boiler room design, foundation drawings etc

AFTER-SALE SERVICE

Full-life After sale service. With our professional technical experts and service team, skilled technology provides customers with professional services

CONSTRUCTION

Our engineer on-site guidance installation and commissioning, ensure boiler running perfect, free training for boiler operator

According to the customer production requirements, provide professional boiler solutions, cost analysis, project investment budget, boiler drawing&installation and commissioning service