Whether you make white wine, beer or wine, you must use steam for the processes involved in their production, such as fermentation and distillation, so it is important to have an industrial steam boiler that can consistently output high temperature, high quality steam. ZOZEN Boiler provided a

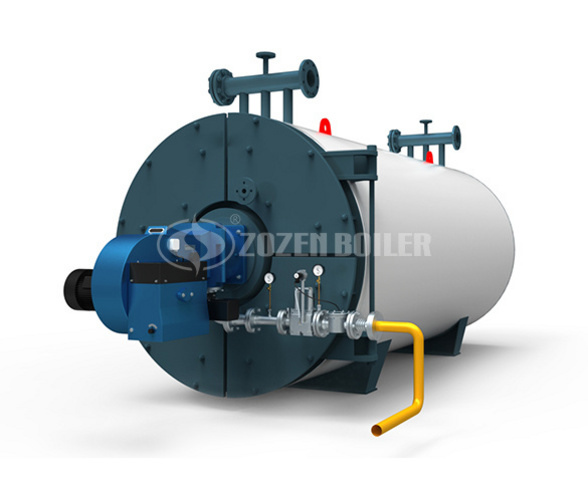

4 ton WNS series gas boiler for a brewery customer. The condenser at the end of this condensing steam boiler uses finned tubes to increase the heating surface and improve heat transfer efficiency, and the finned tubes are made of ND steel to effectively solve the low temperature corrosion of steel.

ZOZEN’s gas boilers are also equipped with intelligent technologies such as automatic water level alarm, automatic feed water adjustment, program start-stop, etc., which can automatically start the automatic protection function when the water level is high or low or the steam pressure is high, guaranteeing the safety of boiler operation and effectively improving the service life of the boiler. After the new 4 ton boiler is put into operation, it runs stably in the brewery and saves energy and reduces consumption for the production process of the enterprise.