Case info

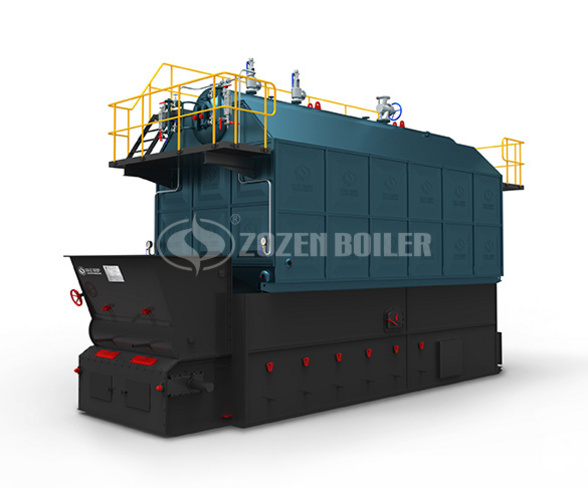

The capacity of SZL series coal-fired steam boilers of ZOZEN Boiler ranges from 4 tons to 35 tons, and the working pressure range is 1 – 2.5 Mpa. The boilers can burn bituminous coal, lean coal, anthracite, etc. The fuel can be selected in a wide range, and local users in Egypt can choose the suitable fuel according to their actual needs.

The boilers are assembled from the factory and consist of two parts, the upper part is the heating surface of the body and the lower part is the combustion equipment, which greatly reduces the technical requirements for boiler installation and the installation period is relatively short. In addition, according to different boiler tonnage, different number of independent air bins are set from front to back of the grate, so that users can reasonably allocate the air according to different combustion conditions to ensure full combustion of fuel, and the thermal efficiency of the boiler can reach over 82%. The customer said that the whole process of cooperation with ZOZEN was very pleasant and efficient.