Case info

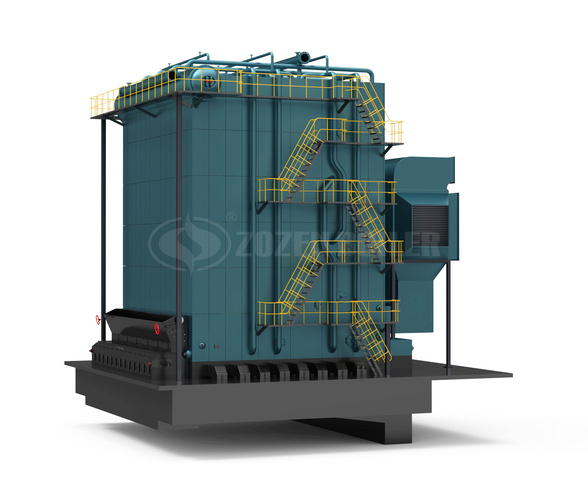

As this paper mill uses 100% imported raw wood pulp as raw material, the production of paper products must be sterilized at high temperatures. Therefore, the customer purchased ZOZEN a set of SZS series 20tph gas-fired boilers, which have full fuel combustion, high efficiency, low energy consumption, clean and pollution-free. This series of gas-fired steam boilers generate high temperature steam through energy conversion to help the production line more effectively complete the cooking and drying of raw materials.

SZS series gas steam boiler using hierarchical combustion and FGR flue gas recirculation two world low nitrogen combustion frontier technology, can reduce NOx emissions to 30 mg/m3 below, fully meet the current most stringent low nitrogen emission standard requirements (30 mg/m3), but also reached the low nitrogen emission combustion technology advanced level. Combined with the high safety of the SZS boiler, up to 98% thermal efficiency, and equipped with intelligent boiler control system, the furnace not only achieve ultra-low nitrogen emissions, but also greatly save energy, has become the best choice of customers in various industries.

Customer feedback

Our company uses 100% imported wood pulp household paper, so it is very important for us to choose a boiler with high efficiency and low energy consumption. By comparison, we purchased ZOZEN Boiler SZS20-2.5-Q condensing gas steam boiler. The boiler is completely combustion, energy consumption is very small, production efficiency is greatly improved, very suitable for our company.