Case info

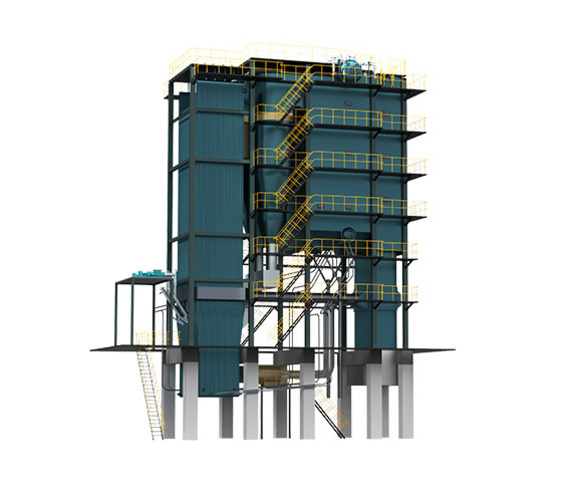

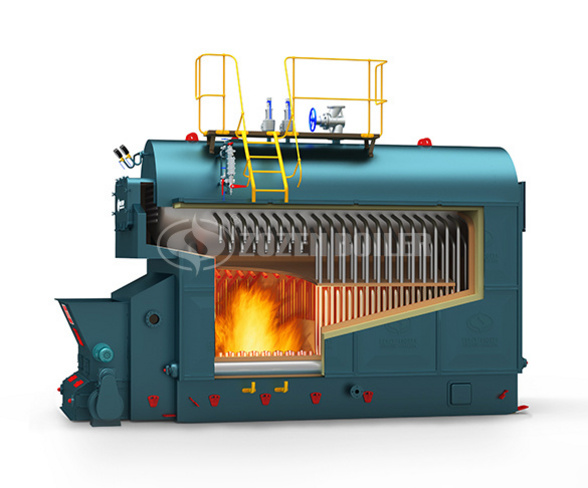

This high efficiency 2000 kw Oil heater boiler is suitable for various types of energy sources, including natural gas, biogas, heavy oil, diesel, etc., so that you can choose the right fuel according to your needs. When configuring auxiliary accessories for customers, imported low-NOx burners are specially selected, which can ensure the full combustion of natural gas and help the paint production line meet the standard of clean production, this series of heat-conducting oil boiler can be paired with various waste heat recovery devices to improve the comprehensive thermal efficiency of the boiler through waste heat recovery and utilization of high-temperature flue gas to achieve greater energy saving, consumption reduction and environmental protection and emission reduction.

After this heat-conducting oil boiler was put into operation for a period of time, ZOZEN’s service team paid a return visit to the customer, who said that the performance of ZOZEN Boiler’s heat-conducting oil boiler is excellent and has provided a solid guarantee for the heat required for the production of the plant since it was put into operation. At the same time, the boiler is equipped with fully automatic operating system, which can automatically control the temperature, pressure, water level, etc. It is also very much in line with our company’s philosophy of pursuing lean production and fully automatic management. After testing, the boiler emissions are also lower than the relevant national standards, which is very green and environmental friendly.