Case info

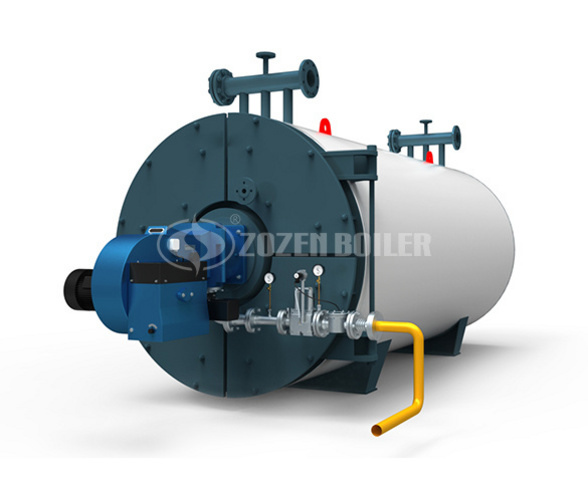

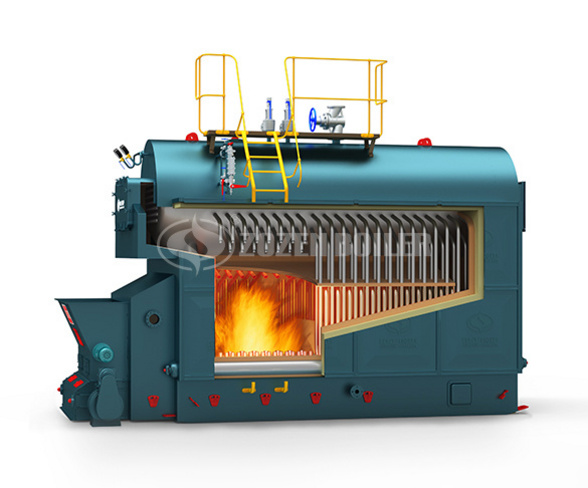

The paper mill customer purchased four sets SZS series gas-fired steam boilers (SZS18-1.6-Q) from ZOZEN, which can fully meet the needs of the production line. The combustion chamber of this gas boiler adopts a full-film water-cooled wall structure, which, together with the large space furnace chamber and low-NOx burner, can achieve a thermal efficiency of over 98% while reducing the amount of NOx produced; the high temperature area of the boiler body adopts forced circulation to ensure that all parts of the heating surface can be reliably cooled and prevented from vaporization. In addition, the fully automatic operation of the boiler can realize unattended operation, which reduces the labor cost for paper enterprises.

Customer feedback

The four boilers produced by Zhongzheng have been put into operation, reducing energy consumption and pollution emissions for our company. We are very grateful to the craftsmanship and professionalism of Zhongzheng boilers for providing a stable steam heat source for our production line, ensuring the quality and output of corrugated paper products, making our company more competitive and having a broader market.