Case info

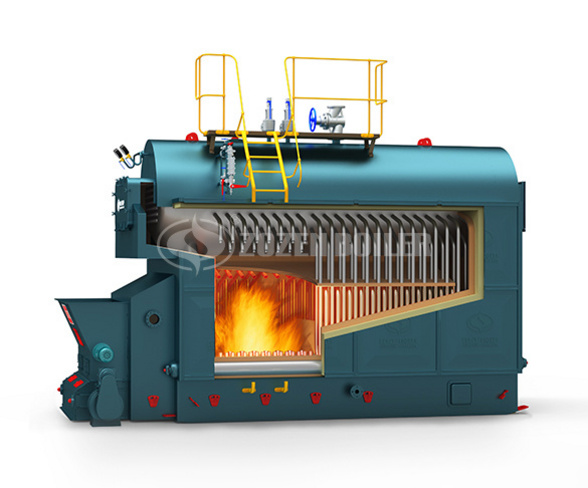

Combining the customer’s requirements and the actual usage needs of the production line, ZOZEN’s designers customized the environmentally friendly SZS series gas steam boiler system for the customer. This model adopts a large volume furnace chamber design with an optional advanced burner, and the NOx emission can be controlled to less than 30mg/m3, effectively reducing environmental pollution.

The SZS series steam boiler adopts D-type arrangement design and full-film water-cooled wall structure to ensure the sealing performance of the boiler. Paired with the spiral finned tube energy saver and condenser at the end of the boiler, the heat loss is effectively reduced and the thermal efficiency of the boiler is increased to over 98%. Meanwhile, ZOZEN’s boiler products are equipped with fully automatic intelligent control system, which can ensure the safe and stable operation of the boiler and reduce the labor cost of enterprises.

Customer feedback

We are grateful to ZOZEN for providing this gas steam boiler, which is energy-saving, efficient, safe and environmentally friendly, saving a lot of fuel and production cost for our company. In addition, we are grateful for the detailed operation guidance and service provided by the technical staff of ZOZEN Boiler, which is considerate and thoughtful and saves our effort!