Case info

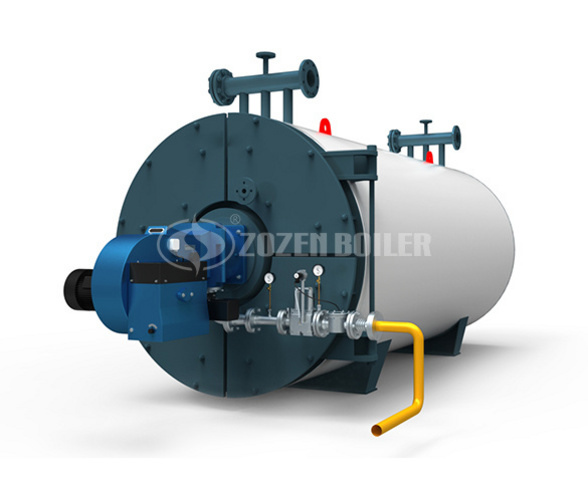

WNS series low nitrogen 2 tons gas boiler heating surface is sufficient, the design has enough large space for water, to ensure the stability of boiler parameters; at the same time, membrane wall structure to ensure excellent sealing performance of the boiler, thermal efficiency can be up to 98% or more. This gas-fired boiler adopts flue gas circulation ultra-low nitrogen burner, which ensures that the fuel is fully burned at the same time, and controls NOx emissions. According to the actual measurement, the average NOx emission concentration is 28mg/m3, which completely conforms to the emission standard of the project area.

Customer feedback

The SZS and WNS series gas steam boilers produced by ZOZEN have not only provided stable and high quality steam heat source for the production line of our company, but also reached the emission targets required by the environmental protection department and passed the acceptance of environmental protection easily after our company was formally put into operation.