Case info

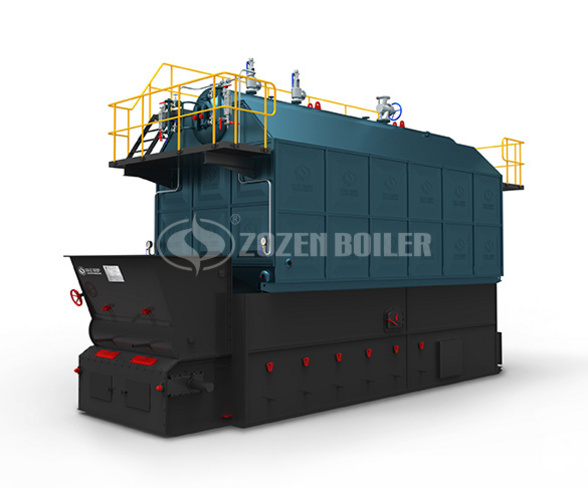

After ZOZEN grasped the customer’s demand for boiler, the first time to communicate the actual gas consumption of the production line, taking into account the food industry for health and safety is very important, engineers for the spice factory customers customized the WNS series 1 ton horizontal steam boiler system solution, this boiler output enough power, high thermal efficiency, low gas consumption, very suitable for small enterprises production line.

This WNS series gas-fired steam boiler adopts large diameter corrugated furnace gall and threaded flue pipe, which can effectively improve the thermal efficiency of the boiler. The boiler is also equipped with energy saving devices such as energy saver and condenser at the end of the boiler, which can effectively recover the waste heat from the high temperature flue gas and reduce the boiler exhaust temperature to 60℃, thus reducing the heat loss and improving the overall thermal efficiency of the boiler.

After the boiler was delivered to the customer and operated at the project site for a period of time, the customer gave high praise to ZOZEN’s service and boiler performance, saying that from boiler selection to after-sales service, every service aspect of ZOZEN Boiler Company is professional and thoughtful.