Case info

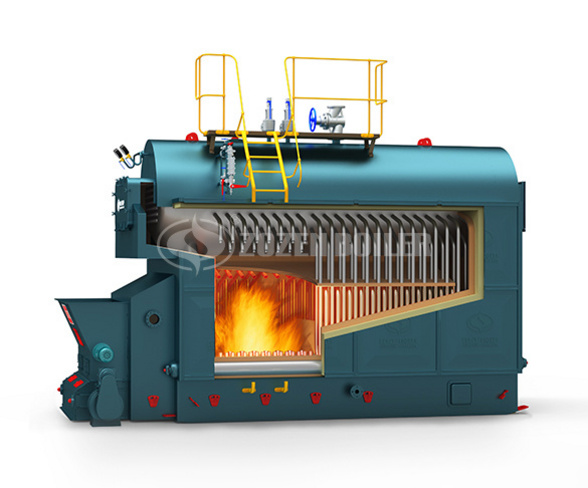

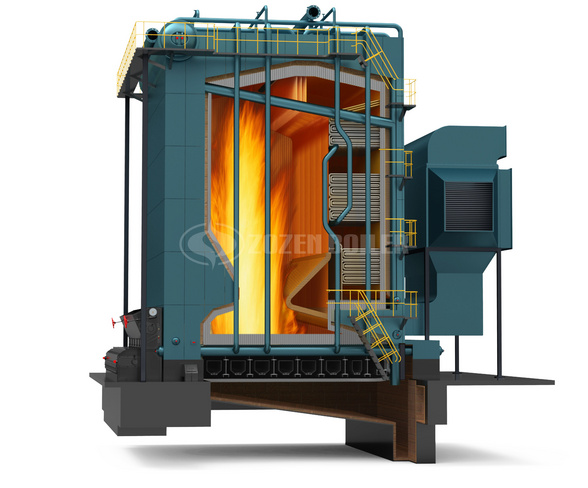

After ZOZEN engineers combined with the actual situation of paper production line, a SZS series condensing gas steam boiler (SZS20-1.25-Q) was recommended for the customer. The SZS series gas-fired steam boiler selected for the program has the advantages of energy saving and environmental protection and high thermal efficiency, and is favored by many paper-making enterprises. This series of boiler adopts the D-type arrangement of double boiler, with scientific and reasonable structure. The furnace chamber adopts narrow spacing tube film type water-cooled wall, which completely seals the furnace chamber and convection tube bundle apart, with good gas tightness and reduced heat loss. At the same time, the radiating heating surface is enlarged, and together with the advanced low-NOx burner, it can ensure the full combustion of fuel, reduce the generation of NOx, and control NOx below 30mg/Nm³, which is not only green but also energy-saving and emission reduction.

The customer is satisfied with the performance of this 20 ton steam boiler produced by ZOZEN during operation. After testing, this SZS gas-fired steam boiler has low emissions and meets national standards, which is very green. It is also worth mentioning that the fully automatic control system, which can automatically adjust the temperature, pressure and water level, etc., is easy to operate and ensures the stable and safe operation of our production line.