Case info

ZOZEN Boiler Company has served many small and medium-sized textile printing and dyeing enterprises, and is experienced in textile industry projects. Usually, small and medium-sized textile factories tend to use small coal-fired steam boilers considering the cost factor. The engineers combined the local situation of Vietnam and the actual needs of the customer’s production line to customize a 10 ton coal boiler system for the customer.

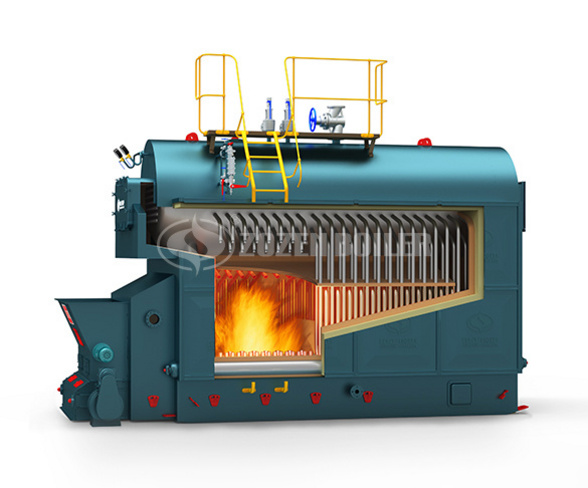

This SZL series coal-fired steam boiler operates efficiently with high overload capacity and wide adaptability to fuel types. In order to achieve accurate air distribution, the technical team has developed and improved the combustion equipment of the boiler, and set up several independent air bins and air regulating doors in the base part, so that the furnace operator can adjust the air intake from front to back of the grate one by one according to the actual type of coal to be burned and the load situation, ensuring that the boiler combustion is always in good condition. In order to help the enterprises’ emission reach the local emission standard, the supporting dust removal equipment is carefully selected, so that the enterprises can use the boiler with confidence.