Case info

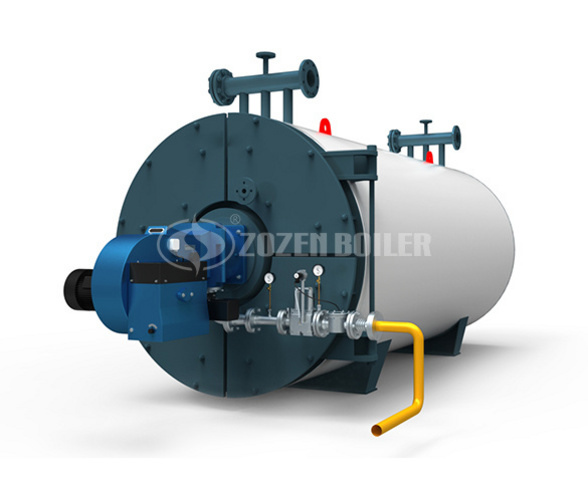

Based on years of experience in serving various industrial industries and careful analysis of the customer’s actual needs, ZOZEN engineers provided the customer with a steam boiler (SZS20-1.25-q) that could meet both environmental requirements and high performance and efficiency. This SZS series gas-fired steam boiler has a compact structure and a small footprint with a double cylinder D-shape arrangement. The boiler is equipped with an advanced low-NOx burner to ensure full combustion of the fuel and effectively suppress NOx generation, with NOx emissions tested to be as low as 30mg/Nm3, meeting stringent environmental requirements. Meanwhile, the SZS series boilers adopt narrow pitch tubular film water-cooled wall in the combustion chamber, which has good air tightness and effectively reduces heat loss, and the thermal efficiency of the boiler can reach 98%, effectively improving the production efficiency of the production line.

During the return visit to the customer, the customer said that this 20 tonnes steam per hour gas oil boiler is in very good running condition and can fully meet the strict environmental requirements of the lithium industry. The fully automatic intelligent control system can easily meet the needs of all-day production, and the steam output is sufficient to help the enterprise save labor costs, so we are very satisfied with this cooperation.