Case info

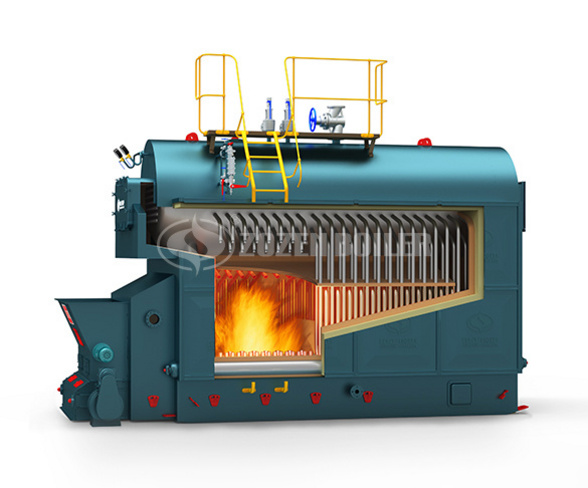

The demand for steam in the textile industry is very high, and the customer attached great importance to the effect of energy saving and emission reduction of the boiler when communicating with ZOZEN engineers. This WNS series fire tube boiler uses clean energy as fuel, and the large diameter design of the full corrugated furnace chamber provides sufficient combustion space, together with the advanced low nitrogen burner to ensure full combustion of fuel. The boiler is equipped with energy-saving equipment at the end to effectively increase the thermal efficiency to 98%, and the high thermal efficiency can also help companies produce further fuel cost savings.

The new WNS series oil gas boiler has a beautiful design and outstanding performance, and is also very easy to install. Through this cooperation the textile factory customer is very satisfied with the service attitude and professional boiler level of the ZOZEN team, saying that it is easy and pleasant to cooperate with such a boiler company that is experienced in projects and considers customers, and looks forward to the next cooperation!